PP Meltblown Non-woven Fabric Extrusion Line: A Game-Changer in the Textile Industry

The textile industry has been revolutionized by the introduction of PP meltblown non-woven fabric extrusion line. This technology has brought about a significant change in the way non-woven fabrics are produced. PP meltblown non-woven fabric extrusion line has become a game-changer in the textile industry, and it has several advantages over traditional non-woven fabric production methods. In this blog post, Jwell will discuss the advantages of PP meltblown non-woven fabric extrusion line.

What is PP Meltblown Non-woven Fabric Extrusion Line?

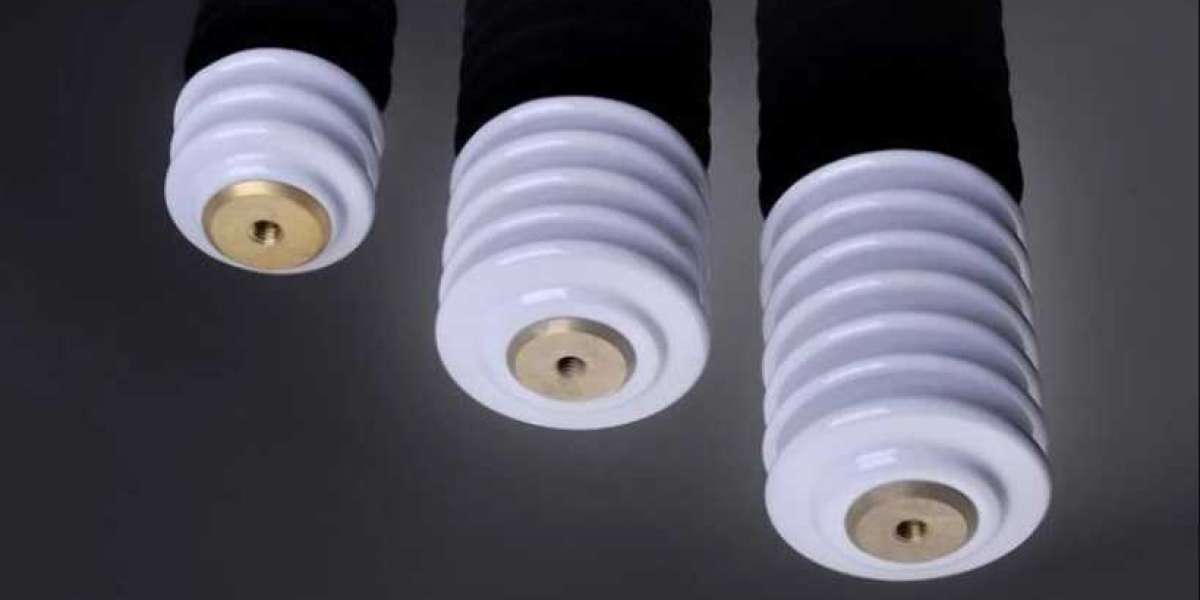

PP meltblown non-woven fabric extrusion line is a technology used to produce non-woven fabrics. The process involves melting polypropylene (PP) pellets and extruding them through a die to form a web of fine fibers. The fibers are then bonded together using heat and pressure to form a non-woven fabric. This technology has been widely adopted in the textile industry due to its numerous advantages.

Advantages of PP Meltblown Non-woven Fabric Extrusion Line

1. High Efficiency

PP meltblown non-woven fabric extrusion line is a highly efficient technology. The process is automated, and it can produce non-woven fabrics at a high speed. The production rate can be adjusted to meet the demand for non-woven fabrics. This technology can produce up to 600 kg of non-woven fabric per hour, which is significantly higher than traditional non-woven fabric production methods.

2. Cost-effective

PP meltblown non-woven fabric extrusion line is a cost-effective technology. The process is automated, which reduces the labor cost. The production rate is high, which reduces the cost per unit of non-woven fabric. The technology also uses less energy compared to traditional non-woven fabric production methods, which reduces the production cost.

3. High-quality Non-woven Fabric

PP meltblown non-woven fabric extrusion line produces high-quality non-woven fabric. The fibers produced by this technology are finer and more uniform compared to traditional non-woven fabric production methods. The fibers are also bonded together using heat and pressure, which results in a stronger and more durable non-woven fabric. The non-woven fabric produced by this technology has a higher filtration efficiency, which makes it suitable for use in various applications.

4. Versatility

PP meltblown non-woven fabric extrusion line is a versatile technology. The process can produce non-woven fabrics of different thicknesses, densities, and colors. The non-woven fabrics produced by this technology can be used in various applications, such as filtration, medical, hygiene, and packaging. The versatility of this technology makes it suitable for use in different industries.

5. Environmentally Friendly

PP meltblown non-woven fabric extrusion line is an environmentally friendly technology. The process uses less energy compared to traditional non-woven fabric production methods, which reduces the carbon footprint. The technology also produces less waste, which reduces the environmental impact. The non-woven fabric produced by this technology is also recyclable, which reduces the amount of waste that ends up in landfills.

6. Easy to Operate

PP meltblown non-woven fabric extrusion line is easy to operate. The process is automated, which reduces the need for skilled labor. The technology also has a user-friendly interface, which makes it easy to operate. The production rate can be adjusted using the control panel, which makes it easy to meet the demand for non-woven fabrics.

Conclusion

PP meltblown non-woven fabric extrusion line has become a game-changer in the textile industry. This technology has several advantages over traditional non-woven fabric production methods. PP meltblown non-woven fabric extrusion line is highly efficient, cost-effective, produces high-quality non-woven fabric, versatile, environmentally friendly, and easy to operate. The technology has been widely adopted in the textile industry due to its numerous advantages. PP meltblown non-woven fabric extrusion line is the future of non-woven fabric production, and it will continue to revolutionize the textile industry.

Suzhou Jwell Machinery Co., Ltd. is an important development strategy center and manufacturing basement under the JWELL GROUP. It is located in Chengxiang Industrial area, Taicang,Suzhou City, 30 minutes far from Shanghai Hongqiao Airport. It covers an area of 20 hectares, and the workshop area is 120000 square meters, equipped with CNC machines and standardized assembly workshop.Welcome to contact us!

https://www.jwellplas.com/Advantages-Of-PP-Meltblown-Non-Woven-Fabric-Extrusion-Line.html