Three-phase EI lamination is a crucial component in the production of electrical transformers and other electrical equipment. The manufacturing process of these laminations involves several intricate steps and techniques to ensure high-quality and efficient performance. In this blog post, we will delve into the detailed manufacturing process of Tianxiang three-phase EI lamination, exploring the materials used, the production steps, and the quality control measures employed to ensure the final product meets the required standards.

Introduction to Tianxiang Three-Phase EI Lamination

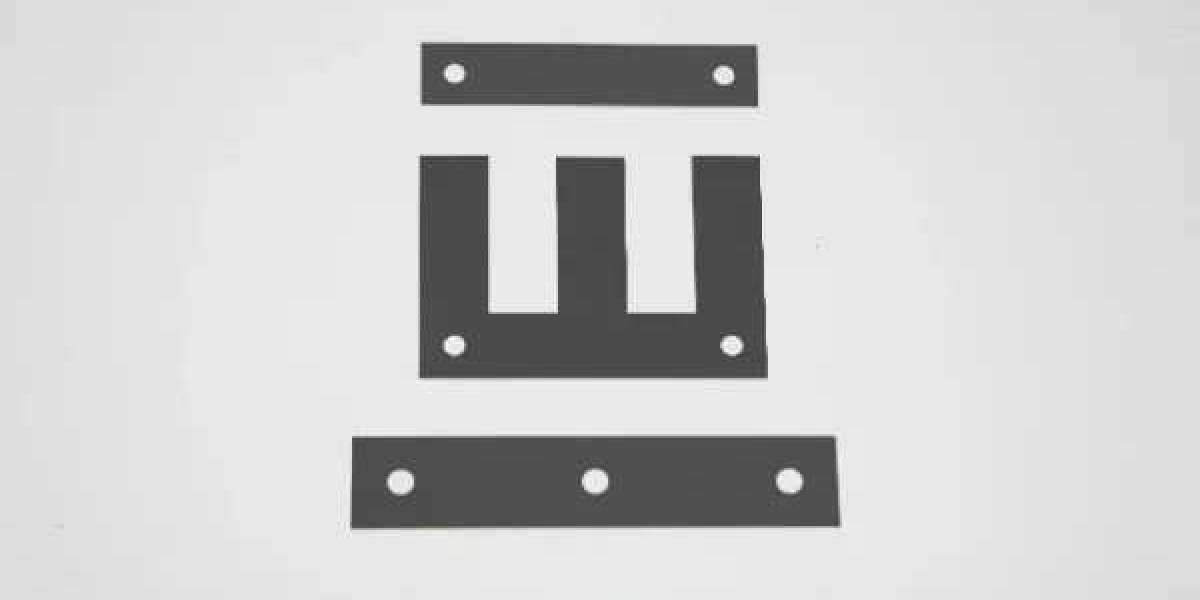

Three-phase EI lamination is a type of electrical steel lamination used in the construction of three-phase transformers, which are essential in power distribution and electrical systems. These laminations are designed to minimize energy loss and improve the overall efficiency of the transformers. The manufacturing process of Tianxiang three-phase EI lamination involves the use of high-quality electrical steel, precise cutting, and stacking techniques, as well as stringent quality control measures to ensure the final product meets the required specifications.

Materials Used in the Manufacturing Process

The manufacturing process of Tianxiang three-phase EI lamination begins with the selection of high-quality electrical steel. Electrical steel, also known as silicon steel, is a specialized steel alloy designed to exhibit specific magnetic properties, making it ideal for use in electrical equipment such as transformers. The primary factors that determine the quality of electrical steel include its magnetic permeability, electrical resistivity, and core loss characteristics.

Tianxiang uses premium-grade electrical steel sourced from reputable suppliers to ensure the lamination's superior magnetic properties and low core loss. The steel undergoes stringent quality checks to verify its chemical composition, magnetic permeability, and surface finish before being approved for use in the manufacturing process.

Production Steps of Tianxiang Three-Phase EI Lamination

The production of Tianxiang three-phase EI lamination involves a series of precise steps to transform the raw electrical steel into the final lamination product. The key production steps include cutting, stamping, annealing, and stacking.

1. Cutting: The first step in the manufacturing process involves cutting the electrical steel sheets into precise dimensions. Tianxiang utilizes advanced cutting machinery equipped with high-precision blades to ensure the accurate dimensions of the individual lamination pieces. The cutting process is critical in achieving the desired shape and size of the laminations, which directly impacts the overall performance of the transformers.

2. Stamping: Once the steel sheets are cut to the required dimensions, they undergo the stamping process. Stamping involves shaping the steel sheets into the specific EI shape, which is essential for assembling the laminations into the transformer core. Tianxiang employs automated stamping machines with custom-designed dies to ensure uniformity and precision in shaping the laminations.

3. Annealing: After stamping, the laminations undergo an annealing process to relieve internal stresses and improve their magnetic properties. Annealing involves heating the laminations to a specific temperature and then slowly cooling them in a controlled environment. This process helps to enhance the magnetic permeability and reduce core loss, resulting in improved efficiency and performance of the transformers.

4. Stacking: The final step in the manufacturing process is the stacking of the individual laminations to form the transformer core. Tianxiang employs automated stacking machines to arrange the laminations in the required sequence and orientation, ensuring optimal magnetic flux distribution within the core. Precision stacking is crucial in minimizing energy loss and maximizing the transformer's efficiency.

Quality Control Measures

Throughout the manufacturing process, Tianxiang implements rigorous quality control measures to ensure the final product meets the highest standards of performance and reliability. Quality control is integrated at every stage of production, from material inspection to final product testing.

Material Inspection: Before the steel sheets are processed, they undergo thorough material inspection to verify their chemical composition, magnetic properties, and surface quality. Any deviation from the specified standards results in the rejection of the material.

Dimensional Accuracy: During cutting and stamping, the dimensions of the individual laminations are closely monitored to ensure they meet the precise requirements. Any deviations are immediately rectified to maintain uniformity and consistency.

Annealing Quality: The annealing process is closely monitored to ensure the laminations achieve the desired magnetic properties and exhibit uniform grain structure. Samples are regularly tested to verify the effectiveness of the annealing process.

Stacking Precision: The automated stacking machines are calibrated to maintain precise alignment and orientation of the laminations. Random samples are inspected to confirm the accuracy of the stacking process.

Final Product Testing: Once the laminations are stacked, the final product undergoes comprehensive testing to evaluate its magnetic properties, core loss, and overall performance. Only the laminations that meet the stringent quality criteria are approved for shipment.

Conclusion

The manufacturing process of Tianxiang three-phase EI lamination is a complex and intricate procedure that involves the use of high-quality materials, advanced machinery, and stringent quality control measures. By adhering to strict production standards and employing precision techniques, Tianxiang ensures that its three-phase EI laminations meet the demanding requirements of modern electrical systems. These laminations play a critical role in enhancing the efficiency and reliability of electrical transformers, ultimately contributing to the seamless operation of power distribution networks and industrial applications.

https://www.jstxgx.com/Manufacturing-process-of-Tianxiang-three-phase-ei-lamination.html