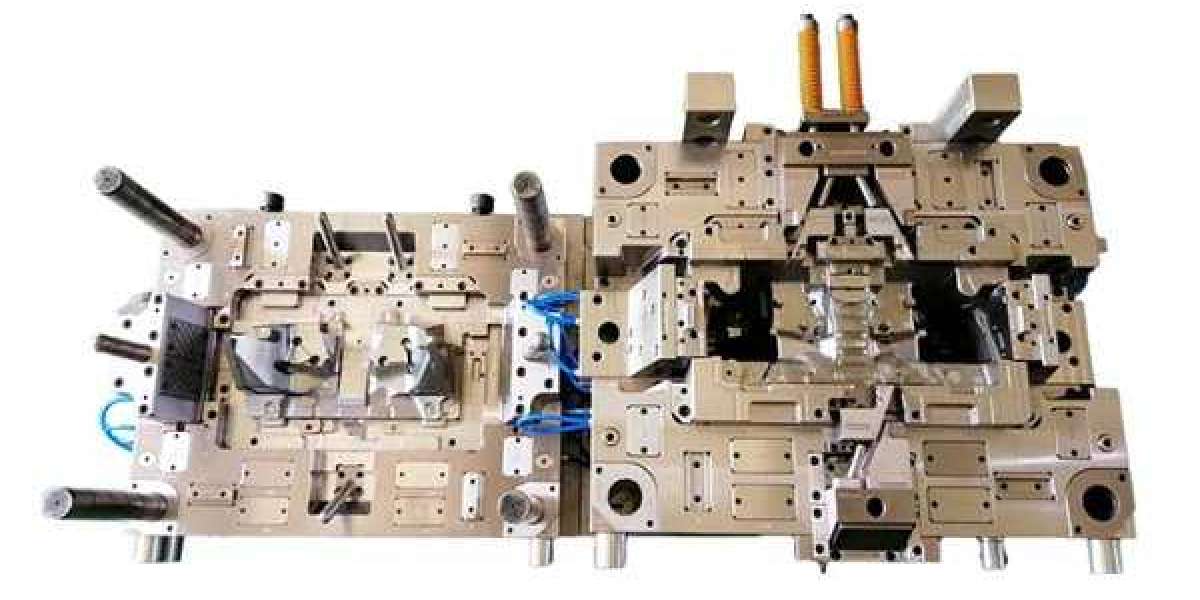

Injection molding is a manufacturing process that has been around for decades. It involves injecting molten plastic into a mold cavity to create a specific shape. This process is used in a variety of industries, including the automotive industry, where it is used to create high precision motorcycle injection molds.

High precision motorcycle injection molds are essential for the production of high-quality motorcycle parts. These molds are designed to produce parts that are accurate, consistent, and of high quality. In this blog post, we will discuss the features of high precision motorcycle injection molds.

1. High Precision

The first feature of high precision motorcycle injection molds is their precision. These molds are designed to produce parts that are accurate and consistent. The molds are made using advanced technology and are designed to meet the exact specifications of the motorcycle parts they are producing.

The precision of the molds is essential because it ensures that the parts produced are of high quality. The molds are designed to produce parts that are free from defects, such as warping, cracking, or uneven surfaces.

2. Durability

The second feature of high precision motorcycle injection molds is their durability. These molds are designed to withstand the high pressures and temperatures involved in the injection molding process. They are made from high-quality materials that are resistant to wear and tear.

The durability of the molds is essential because it ensures that they can be used for a long time without needing to be replaced. This reduces the cost of production and ensures that the parts produced are of consistent quality.

3. High-Quality Materials

The third feature of high precision motorcycle injection molds is the use of high-quality materials. These molds are made from materials that are resistant to wear and tear, such as hardened steel or aluminum. The materials used are also resistant to corrosion, which ensures that the molds can be used for a long time without rusting.

The use of high-quality materials is essential because it ensures that the molds can withstand the high pressures and temperatures involved in the injection molding process. It also ensures that the parts produced are of high quality and free from defects.

4. Advanced Technology

The fourth feature of high precision motorcycle injection molds is the use of advanced technology. These molds are designed using computer-aided design (CAD) software, which allows for precise and accurate designs. The molds are also made using computer numerical control (CNC) machines, which ensures that the molds are produced to exact specifications.

The use of advanced technology is essential because it ensures that the molds are designed and produced to the highest standards. It also ensures that the molds are consistent and accurate, which results in high-quality parts.

5. Customization

The fifth feature of high precision motorcycle injection molds is their customization. These molds can be customized to meet the specific needs of the motorcycle parts being produced. The molds can be designed to produce parts of different shapes, sizes, and materials.

The customization of the molds is essential because it ensures that the parts produced are tailored to the specific needs of the motorcycle manufacturer. It also ensures that the molds can be used for a variety of different parts, which reduces the need for multiple molds.

Conclusion

High precision motorcycle injection molds are essential for the production of high-quality motorcycle parts. These molds are designed to produce parts that are accurate, consistent, and of high quality. The features of these molds include high precision, durability, high-quality materials, advanced technology, and customization.

The precision of the molds ensures that the parts produced are free from defects, while the durability ensures that the molds can be used for a long time without needing to be replaced. The use of high-quality materials and advanced technology ensures that the molds are designed and produced to the highest standards. Finally, the customization of the molds ensures that the parts produced are tailored to the specific needs of the motorcycle manufacturer.

Xuzhong Technology (Shenzhen) Co., Ltd. is located in Shenzhen, China, adjacent to Hong Kong. We are a company focusing on exporting mold business.We remain committed to delivering high quality, tight tolerance contract plastic injection molds.Provide high-quality mold products and high-quality services to global customers. Xuzhong is committed to high precision motorcycle injection mold supply, we will provide you with high-quality products and considerate services. Welcome to inquire.

https://www.xuzhongmold.com/Features-of-high-precision-motorcycle-injection-mold.html